When it comes to industrial inspections, choosing the right camera can make all the difference. Two of the most common types of inspection cameras are flexible scopes and rigid scopes. Each has unique strengths, limitations, and ideal applications. This guide will help you understand the differences between these tools and determine which type of camera is best for your inspection needs, whether you’re performing maintenance, quality control, or industrial safety checks.

Understanding Flexible and Rigid Scopes

Flexible Inspection Cameras

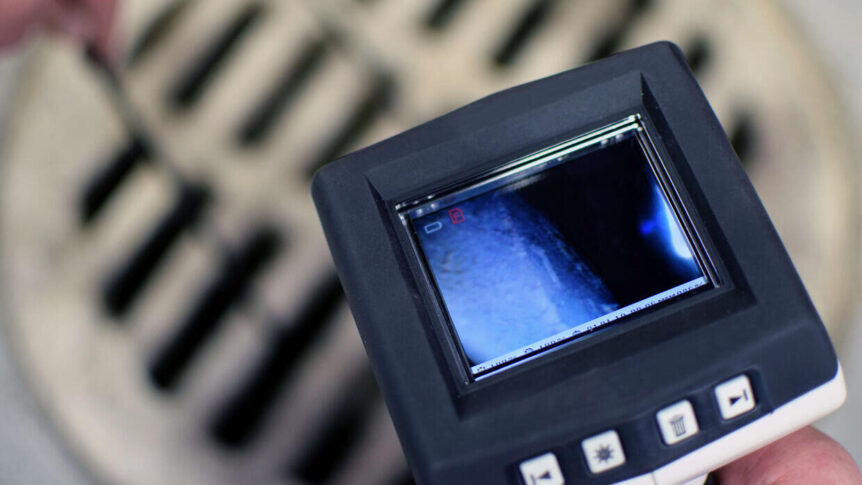

Flexible inspection cameras, often referred to as flexible scopes, feature a bendable probe that can navigate tight spaces, corners, and complex machinery. They are designed for situations where direct line-of-sight inspections are impossible.

Advantages of Flexible Scopes:

- Versatility: Can bend around corners and access confined areas.

- Portability: Lightweight and easy to maneuver.

- Real-time inspection: Offers live imaging to detect problems quickly.

Limitations:

- May provide less precision in straight-line measurements.

- The probe can be more fragile if not handled carefully, especially when bending sharply.

Rigid Inspection Cameras

Rigid inspection cameras, or rigid scopes, feature a solid, straight probe. They excel in durability and provide high-quality images for inspections where the passage is straight or mostly unobstructed.

Advantages of Rigid Scopes:

- Durability: Can withstand rough industrial handling.

- Superior image quality: Often provides sharper images with more consistent lighting.

- Precise measurements: Ideal for straight-line inspections where accuracy is key.

Limitations:

- Cannot navigate curves or complex pathways easily.

- Less versatile in tight or twisted spaces compared to flexible scopes.

Rigid Scope vs Flexible Scope: Key Differences

When weighing a rigid scope vs flexible scope, consider these key factors:

| Feature | Rigid Scope | Flexible Scope |

| Flexibility | Fixed, straight probe | Bendable, navigates curves |

| Durability | High; withstands rough handling | Moderate; probe can be damaged if bent excessively |

| Image Quality | Often superior | Good; may vary depending on probe length and bending |

| Best For | Straight passages, shafts, turbines | Complex machinery, corners, hard-to-reach areas |

| Ease of Use | Simple, stable | Requires careful manipulation and skill |

Understanding these differences is essential to choosing the right inspection camera for your work environment.

When to Choose a Flexible Scope

A flexible scope is ideal when:

- Inspections require navigating machinery with complex internal pathways.

- Access points are limited or obstructed by bends and curves.

- Portability and versatility in the field are necessary.

Common applications include plumbing inspections, HVAC ductwork checks, automotive engine diagnostics, and industrial machinery inspections that involve corners or narrow spaces.

When to Choose a Rigid Scope

A rigid scope is the best choice when:

- Straight-line inspections are needed, such as pipelines, mechanical shafts, or turbines.

- Durability and resistance to rough handling are critical.

- Precise measurements or superior image quality are required.

Examples include boiler inspections, straight duct inspections, and turbines or engines where direct line-of-sight imaging is sufficient.

Practical Tips for Using Both Types of Scopes

- Know your inspection environment: Choose a rigid or flexible scope depending on whether the path is straight or curved.

- Consider probe length: Longer flexible scopes can reach deeper areas but may require more skill to maneuver.

- Check lighting options: While both types often have LED lighting, rigid scopes usually provide more even illumination.

- Maintain your equipment: Clean lenses and handle flexible probes carefully to prolong their lifespan.

- Train your team: Proper handling ensures accurate inspections and reduces risk of damage to the camera.

Combining Both for Maximum Efficiency

Many inspection professionals keep both rigid and flexible scopes in their toolkit. Having both ensures you are prepared for any scenario:

- Use flexible scopes for hard-to-reach, curved, or confined areas.

- Use rigid scopes for straight-line, high-precision inspections where durability and image clarity matter most.

By understanding the strengths of each type, you can optimize inspections, reduce downtime, and maintain safety.

Choosing the Right Inspection Camera

When deciding between a rigid scope vs flexible scope, the best choice depends on the environment and inspection requirements. Flexible scopes provide unmatched versatility and access, while rigid scopes offer durability and precise imaging. Many industrial professionals find that using both types ensures comprehensive coverage for all inspection tasks.

USA Borescopes offers a wide range of both rigid and flexible inspection cameras, designed for industrial, automotive, and maintenance applications. By selecting the right type of scope for each task, you can ensure accurate, efficient, and safe inspections every time.

The post Flexible vs. Rigid Inspection Cameras: Which Is Best? appeared first on USA Borescopes.

Source: usaborescopes.com